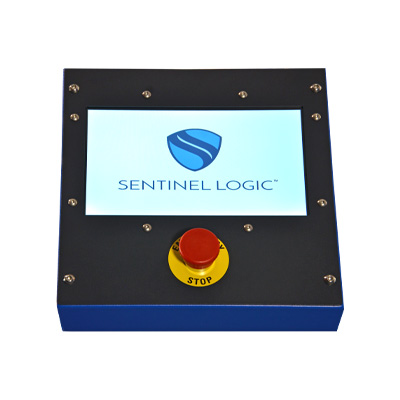

VersaMix Front View

The VersaMix® meter mix system is designed to simplify two component dispensing with a versatile, highly engineered design. This dual servo-driven, variable ratio system offers ultimate control of shot size and volume with repeatable results across materials. It is ideal for a range of applications like potting, CIPG, FIPG, syringe filling, filament winding, RTM, VARTM, flexible packaging/converting, and encapsulation, and is compatible with nearly any viscosity.

Users can accurately proportion materials to exact volumetric mix ratios from 1:1 to 10:1 thanks to a gravity fed piston displacement pump. The system can handle epoxies, urethanes, silicones, and more, with a variety of optional add-ons to customize for your unique application needs.

| Variable flow rate |

| Independent speed control of dissimilar materials |

| Programmable dispense volumes |

| Compatible with mildly abrasive materials |

| Easy-to-navigate Sentinel Logic™ software |

| Gravity fed |

| 10 to 15 cycles/min or more (dependent on viscosity) |

| High and low level sensing |

| Ratio Range | 1:1 to 10:1 |

| Drive System | Dual servo driven |

| Metering Device | Piston displacement |

| Viscosity Range | Liquid to paste |

| Standalone Design | 12 in x 26 in x 50 in |

| Electrical Requirements | 240 VAC |

VersaMix® Changing the Game with 2K Meter Mixing

The VersaMix® meter mix system is designed to simplify two component dispensing with a versatile, highly engineered design.

In this video you will see a brief demonstration on how to calibrate the VersaMix® Two Component Meter Mix System.